Compound robot, future trend

Personalized flexible manufacturing is the development trend of smart factories in the future, and the demand for flexible automation equipment is more urgent. Compared with the single function of agv/amr and manipulator, the composite robot combining the two characteristics is obviously more flexible.

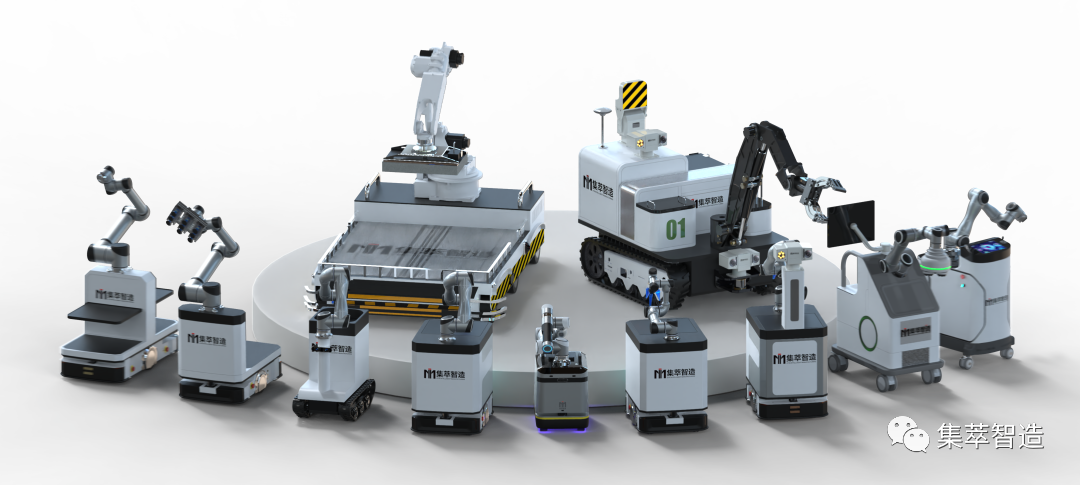

The collective intelligent manufacturing composite robot is composed of cooperative robots and mobile robots. It adopts laser navigation technology, is equipped with built-in sensors, cameras and mature software. During the operation, it presents "eyes", "hands" and "feet" that are very close to the human state. It can perform difficult tasks that traditional robots cannot complete, and will fully release the application potential of robots in more new scenes.

Three advantages of brain eye hand foot robot Effectively improve the degree of automation and create a flexible production process

There are extreme situations in some industries, either full automation or no automation. Composite robots can bridge this automation gap. Based on the flexible safety of cooperative robots and the flexibility of mobile robots, they can be configured into production processes such as extraction, transportation and assembly through simple operations, so as to achieve the integration of high efficiency, continuity, accuracy, flexibility and safety.

Operations can be carried out according to the sequence of operations, or multiple machines can work together to form a highly flexible flexible production line.

It can replace manual work to complete dangerous operations in harsh environment

There are harmful dusts in the working environment of some industries. Sometimes, the detection industry involves high-risk environmental detection. There is an infection risk in the disinfection disinfection and sterilization during the epidemic, which more or less affects the health of the staff. The compound robot can replace the manual to complete the dangerous operation in the harsh environment, and greatly improve the working conditions of personnel. At the same time, some simple but cumbersome handling work can be replaced by composite robots, which can avoid accidents caused by human fatigue or negligence.

Flexible use, wide range of industry applications

In the field of industrial manufacturing, it is difficult for a single fixed position robot to build an all-round intelligent factory. In order to reduce costs, enterprises need robots to "move" to realize the connection of end-to-end equipment, including the connection of intelligent logistics through composite robots, and promote the realization of a complete set of industrial chain software and hardware combination from production to logistics upstream and downstream of the whole factory, The unique application value of "brain, eye, hand and foot" of the composite mobile robot expands the boundary of the mobile robot and can go deep into more scenes and links.

Secondly, in the field of life services, with the arrival of the epidemic era, all walks of life have unconsciously realized historical changes. For the need of epidemic prevention, to avoid mutual infection between people, composite mobile robots have been applied in new scenarios that are constantly expanding, such as robot people using their arms to make coffee, picking fruits, spraying pesticides, cleaning, mobile supermarket salespeople, replacing disinfection and sterilization operations on various occasions, and so on.

Key core technologies and advantages of compound robot

In the past, the common composite robots in the industry were assembled and redeveloped by integrators who purchased different mechanical arms, AGVs and other products, which led to the failure of the integration of the robot control system. Due to the different controllers of each sub unit and the completely different internal communication protocols, it was difficult for buyers to use and made frequent mistakes.

By virtue of its strong R & D strength, Jiji intelligent manufacturing has designed a series of composite mobile robot systems according to the needs of multiple complex operation scenarios. On the mechanical structure and control system, the arm and mobile chassis are integrated, and have a unified control system. On this basis, Jiji intelligent manufacturing has overcome the current detection system and sensing system technology, adaptive control algorithm, dynamic modeling, safety collision detection algorithm, and natural human-computer interaction, Key technologies such as path planning in the man-machine integration environment have been developed, and key core components such as high power density ratio drive control integrated joint and permanent magnet brushless torque motor have been developed, effectively solving the problem that similar domestic products rely on imports.

Compared with foreign products, the product has obvious cost performance advantages, and the later maintenance costs are also significantly reduced, effectively saving users' intelligent manufacturing costs.

Compound robot

case

The application scenarios of composite robots are often non-standard. Different configurations and deployments are required according to the different environment. Many cases can show that collective intelligent manufacturing can respond faster and better to customized needs.

Complex environment disinfection and sterilization, robot "Replacing" artificial

With the repeated epidemics, the cleaning, sterilization and dust removal work in public spaces such as high-speed service areas, airports and trains is increasingly faced with the problem of "difficult recruitment and management" due to certain risks, high labor intensity and other factors.

According to the disinfection and sterilization needs of airports, stations, hotels, hospitals and other scenes, the intelligent manufacturing self-developed and designed composite robots are gathered, and dust removal plates, anti-virus UV lights, spray and other equipment are installed at the end. The lightweight and large load cooperation function of the cooperative robot and the mobile operation function of AGV are used to jointly complete the cleaning, disinfection, dust removal and other work in complex scenes such as trains and toilets.

Maintenance and assembly, and the compound robot "has multiple functions"

According to the customer's scenario requirements, the maintenance robot built by Jiji intelligent manufacturing can perform two types of scenario tasks: disassembly and assembly.

When performing the disassembly task, the collective intelligent manufacturing composite robot can automatically disassemble the screws, grasp, pull out, and carry the modules that have problems.

When performing the assembly task, in order to meet the operation requirements of customers, the composite robot can enter the designated position under manual operation, switch the man-machine cooperation mode, and complete the assembly of electronic modules together with people, which not only improves the operation efficiency, but also reduces the labor intensity of workers.

Workpiece handling, composite robot assisted production

The problems of waste of space, excessive handling personnel and low operation accuracy in traditional factories will be successfully solved with the application of composite robots and related technologies.

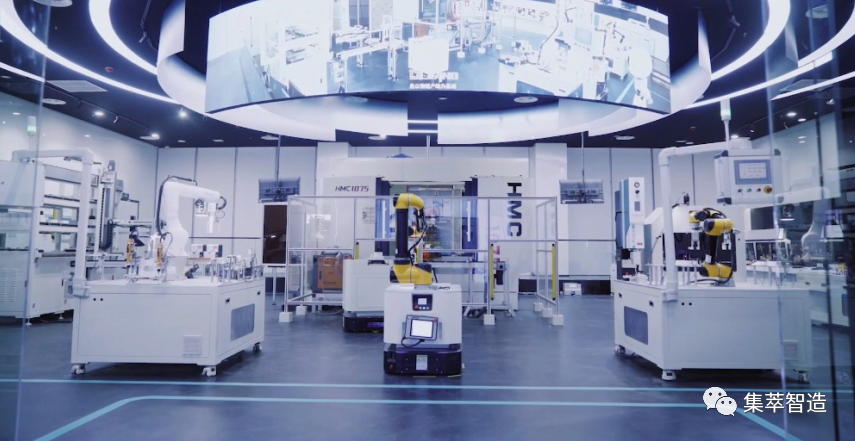

In the intelligent speaker production demonstration line created by Jicui intelligent manufacturing, the composite robot replaces the traditional conveyor line and rail conveyor system to undertake the processing, personalized customization, assembly and packaging and delivery of transfer between multiple production units, flexibly twists in a limited space, and realizes the accurate distribution of materials among multiple production units.

It has been proved that the composite robot can significantly reduce the number of handling personnel in the workshop, reduce the handling times and improve the operation accuracy.

summary

The results of a number of intelligent factories and robot application projects designed and implemented by intelligent manufacturing show that the "flexible flow" of composite robots in the production line has optimized the work process, and its production capacity and space utilization have also been significantly improved.

The incremental market of composite mobile robots has great potential, but the current demand for composite mobile robots is only the tip of the iceberg. With the development and progress of science and technology, composite mobile robots will be applied in all fields around life, including military applications, industrial manufacturing, medical rehabilitation, life services, agricultural picking, intelligent inspection, etc.